Building a low-carbon future: Reducing embodied carbon in the built environment

On May 31, 2019, the Embodied Carbon in Buildings conference, organized by the BSA in partnership with MIT, addressed what the embodied carbon footprint of buildings is, why it matters, and what the building industry can do about it.

Embodied carbon is an emerging but important topic of discussion among the sustainable design community. Source: Architecture2030

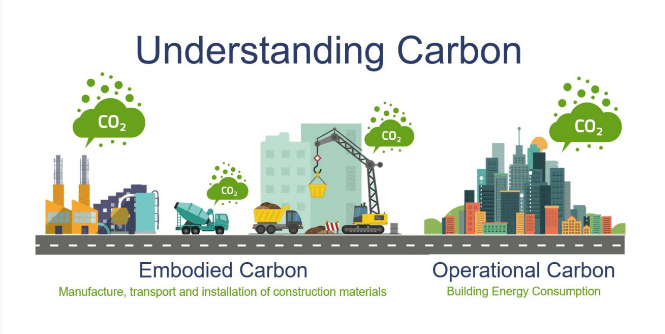

The atmosphere at the conference was abuzz with excitement. The sold-out event had 200 attendees comprising of representatives from across the building industry: architects, engineers, and contractors all united to discuss solutions to the impact of embodied carbon, which includes the carbon footprint from the manufacturing, transportation and installation of construction materials.

So what’s the buzz all about?

Considering that buildings generate nearly 40% of greenhouse gas (GHG) emissions each year, about a third of which has come from the building materials alone, members of the design community have realized they are confronted with a growing problem.

If new buildings are designed and constructed in the ‘business as usual’ manner, embodied carbon will make up almost half of total new construction emissions.

“As buildings become more energy efficient to operate, the relative importance of embodied energy increases,” Executive Director of the Carbon Leadership Forum, Kate Simonen, says in her presentation at the conference.

A clear pathway to reducing embodied carbon in buildings can be led by architects, as they have purchasing influence on building material selection.

As Stephanie Carlisle, an architect at KieranTimberlake who presented at the conference points out, “Architects must “put carbon numbers on the table when making design decisions–period.”

Stephanie Carlisle of architecture firm KieranTimberlake says architects must “put carbon numbers on the table when making design decisions–period.”

One key strategy for reducing embodied carbon involves incorporating innovative technology into the manufacturing process of the materials. This is becoming more widespread as carbon capture storage and utilization (CCUS) technologies are being developed worldwide.

To enable the maximum embodied carbon reduction, materials with higher carbon footprints must be targeted. One such material is concrete; which also happens to be the most abundant man-made material in the world.

Due to the energy intensive process of making cement, a key ingredient in concrete, concrete is responsible for about 7% of global carbon dioxide (CO2) emissions. Thus it is crucial to reduce the carbon footprint of concrete in order to successfully reduce the embodied carbon footprint of new buildings.

According to Jeremy Gregory, the Executive Director of the MIT Concrete Sustainability Hub, there are several existing ways to reduce the carbon footprint of concrete, such as using alternative fuels while making cement and by replacing cement altogether with other, technologically developed materials, such as graphene.

A solution for reducing the embodied carbon of concrete lies in the ability to sequester carbon within the concrete itself, via carbon capture and utilization (CCU) technologies.

Canadian company CarbonCure Technologies is on a mission to reduce the carbon footprint of the built environment. The CarbonCure Technology enables ready mix concrete producers to add post-industrial CO2 into their concrete mixes, which then increases the concrete’s compressive strength, thereby allowing for a reduction in the mix’s cement content. The injected CO2 chemically converts into a mineral, permanently sequestering the CO2, while further minimizing the concrete’s carbon impact by reducing its most carbon-intensive ingredient.

Concrete masonry producers can use the CarbonCure Technology to permanently sequester post-industrial CO2 into their masonry products. Concrete masonry already uses less cement than ready mix concrete thanks to the increased strength gained by the compaction process.

Jandris Block, a concrete masonry manufacturer based in Gardner, Massachusetts, is a CarbonCure supplier in the region. Since installing the CarbonCure Technology in 2014, the company has supplied more than 170,000 concrete masonry units made with recycled CO2 to multiple jobs in the Boston area. In total, Jandris Block has saved about 5,700 pounds of carbon emissions from entering the atmosphere, which is equivalent to the amount of carbon sequestered by 3 acres of forest in one year.

For Heidi Jandris, who is a trained architect and the Technical Resource and Sustainability Manager at Jandris Block, adding CarbonCure to her family’s masonry plant was a no-brainer, as it fit in with the company’s many initiatives to become more sustainable.

“CarbonCure came to us speaking of innovative solutions to make concrete products more sustainable,” Jandris says. “I wanted to be a part of that conversation.”

Heidi Jandris of Jandris Block is a champion of sustainability. By using the CarbonCure Technology, Jandris Block has saved 5,700 pounds of carbon emissions.

Since installing the CarbonCure Technology, Jandris has supplied blocks made with CarbonCure for a variety of projects, ranging from buildings at the MIT campus in Cambridge, to the MGM Casino and Resort in Springfield, whose request for CarbonCure block was mandated in its specifications.

For the MGM Casino project, Jandris saved 1,900 pounds of embodied carbon by providing blocks made with CarbonCure. That is equivalent to the amount of carbon sequestered by one acre of forest in a year, or the amount of emissions from 2,100 miles driven by an average passenger vehicle.

Jandris Block has also been focused on becoming more sustainable in its operations. For example, Jandris says that the plant gets on average 80% of its electricity from solar panels, and about 10 years ago they update their kilns so that they were able to lower their fossil fuel consumption by about 50%.

As well, in 2016 Jandris Block became the first concrete masonry manufacturer on the east coast to publish environmental product declarations (EPDs).

“We got an EPD for every single one of our mix designs,” Jandris says. “So now we have a really good starting point, and we know how we can improve our sustainability moving forward.”

Though Jandris Block has been ahead of the game when it comes to sustainability initiatives, the company is not alone in its desire to identify and deploy solutions that reduce embodied carbon in new buildings.

Structural engineers are also joining the movement, with organizations such as SE2050 leading the charge to encourage structural engineers to review prescriptive specification practices that can limit concrete producer’s ability to adopt innovative low-carbon solutions, such as CarbonCure. Many structural engineers are encouraging firms to shift towards performance-based specifications to enable a wide range of carbon-reducing strategies while meeting quality performance criteria.

“Performance-based specifications are the best way to spur innovation in low-impact concrete,” Jeremy Gregory says.

Transitioning to performance-based specifications requires a fundamental paradigm shift among the design and construction community, which is only achievable through collaboration among all stakeholders.

In other words, when architects, engineers, and contractors are willing to come together, share new ideas, be open to change and discuss solutions, as they did that day at the Embodied Carbon conference, significant reductions to embodied carbon can be achieved today.

CarbonCure was a Premium Sponsor at the Embodied Carbon in Buildings Conference on May 31, 2019. The conference was organised by the BSA in partnership with MIT.

The BSA staff and members are not responsible for the content or accuracy of this post.